I-Waspaloy - I-Alloy Ehlala Ihleli Kwizicelo Zobushushu Obuphezulu

| I-alloy | into | C | Si | Mn | S | P | Mo | Cr | Al | Ti | Fe | Cu | B | Zr |

| I-Waspaloy | Ubuncinci | 0.02 | 3.5 | 18.0 | 1.2 | 2.75 | 0.003 | 0.02 | ||||||

| Ubuninzi | 0.10 | 0.75 | 1.0 | 0.03 | 0.03 | 5.0 | 21.0 | 1.6 | 3.25 | 2.0 | 0.5 | 0.01 | 0.12 | |

| enye | I-Co:12.0~15.0,Ni:ibhalansi | |||||||||||||

| Isimo se-Aolly | Tensile strength RmUbuncinci I-Mpa | Unikeze Amandla RP 0.2I-Min Mpa | Ukwandiswa A 5Ubuncinci% | Ukunciphisa yoMmandla,umzuzu, % | Ubunzima bukaBrinell HB |

| isisombululo+ ukuzinzisa+ukuqinisa imvula | 1100 | 760 | 15 | 18 | 310 |

| Uxinanog/cm3 | Indawo yokunyibilika℃ |

| 8.19 | 1330~1360 |

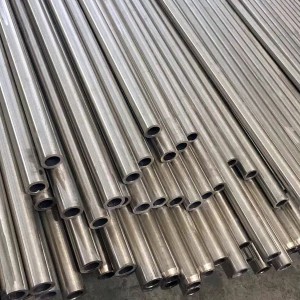

Intonga, iBha, iWire kunye neForging Stock- ASTM B 637, ISO 9723, ISO 9724, ISO 9725, SAE AMS 5704, SAE AMS 5706,

Ipleyiti, Iphepha kunye neStrip -I-SAE AMS 5544

Bhala umyalezo wakho apha uze uwuthumele kuthi