I-Nickel Alloy 20 (UNS N08020) /DIN2.4660

| I-alloy | into | C | Si | Mn | S | P | Ni | Cr | Nb+Ti | Fe | Cu | Mo |

| I-alloy 20 | Ubuncinci |

|

|

|

|

| 32.0 | 19.0 | 8*C |

| 3.0 | 2.0 |

| Ubuninzi | 0.07 | 1.0 | 2.0 | 0.035 | 0.045 | 38.0 | 21.0 | 1.0 | ibhalansi | 4.0 | 3.0 |

| Isimo se-Aolly | Tensile strength Rm Mpa Ubuncinci. | Unikeze Amandla RP 0.2 Mpa Ubuncinci | Ukwandiswa A 5 ubuncinci % |

| I-Annealed | 620 | 300 | 40 |

| Uxinanog/cm3 |

| 8.08 |

Intonga, iBha, iWire kunye neForging Stock- ASTM B 462 ASTM B 472, ASTM B 473, ASME SB 472, ASME SB 473,

Ipleyiti, Iphepha kunye neStrip- ASTM A 240, ASTM A 480, ASTM B 463, ASTM B 906, ASME SA 240,

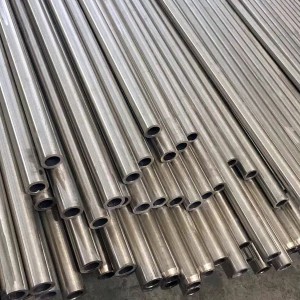

Umbhobho kunye neThubhu- I-ASTM B 729, I-ASTM B 829, I-ASTM B 468, I-ASTM B 751, I-ASTM B 464, I-ASTM B 775, I-ASTM B 474,

Okunye- I-ASTM B 366, I-ASTM B 462, I-ASTM B 471, I-ASTM B 475, I-ASME SB 366, I-ASME SB-462, I-ASME SB

Ukumelana okugqwesileyo kokugqwala kwi-sulfuric acid

Ukumelana okuhle kakhulu nokuqhekeka koxinzelelo lwe-chloride

Iipropati ezigqwesileyo zoomatshini kunye nokukwazi ukwenziwa

Imvula encinci ye-carbide ngexesha lokuwelda

Igqwesile ekumelaneni nokugqwala kwii-acids ezishushu ze-sulfuric